Birmingham New Street has undergone a major transformation and mastic asphalt has ensured that the Station’s car park remains waterproof.

Located in Birmingham city centre, the railway station is a central hub of the British transport network. Prior to its five-year, £750m transformation as part of the Birmingham Gateway project, the station was considered to be very dark and grey. It was even voted as “the second biggest eyesore in the UK”’ by readers of Country Life magazine. (Wind farms topped that particular poll).

The redevelopment of the station was necessary not only to modernise the structure so it could meet the ever-increasing demands of today’s rail transport requirements, but to reconnect the north and south side of Birmingham for the first time since the arrival of the railway in the 19th century.

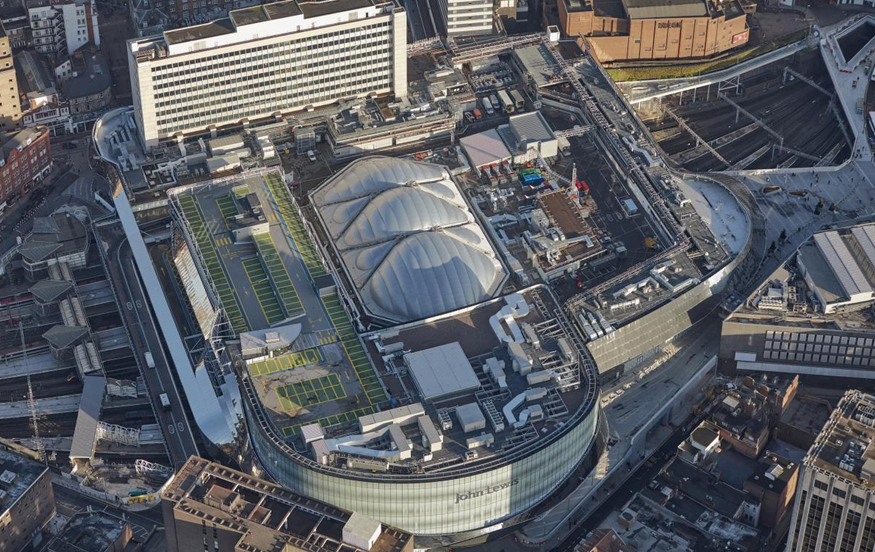

Birmingham New Street is now one of Britain’s busiest interchange stations, used by up to 170,000 passengers every day. Such is its scale that the passenger concourse is five times the size of London’s Euston and the station has over 40 shops at concourse level, above which is the Grand Central shopping complex, featuring one of the UK’s largest John Lewis department stores.

And above the station itself is an expanse of rooftop parking.

The car park and associated retail service deck perform a critical function in helping the station and shopping complex run smoothly. Ensuring the deck of this parking facility remains waterproof is vitally important to operation of the station.

When Network Rail decided to renovate the deck its management contractor Mace turned to specialist waterproofing contractor BriggsAmasco, which carried out the deck refurbishment using a mastic asphalt screeding system.

BriggsAmasco, which is a Mastic Asphalt Council (MAC) contractor member, was commissioned to design, supply and installation of approximately 15,000m2 of mastic asphalt screeding systems across the site.

The station had to remain open and fully operational throughout the refurbishment, so it was critical that the mastic asphalt screeding application was carried out with minimal disruption on-site. BriggsAmasco also had to ensure that the deck waterproofing element was delivered in line with the tight construction programme.

As well as working 38,700 man-hours on-site with a 40-strong team, BriggsAmasco provided around-the-clock callout cover to manage and resolve issues associated with what was a complex rebuild. Working in 24-hour shifts and taking deliveries overnight to avoid disrupting day-to-day operations, the company maintained a hassle-free site without any compromise on product performance or working practices.

Despite the challenges of working to extremely tight deadlines, health and safety was absolutely paramount on this Network Rail site. At Birmingham Gateway, every operative was qualified under either the Site Supervisors Safety Training Scheme (SSSTS) or Site Management Safety Training Scheme (SMSTS).

Visits to site every week from a company director and a dedicated safety manager helped ensure that there were no RIDDOR (Reporting of Injuries, Diseases and Dangerous Occurrences) incidents over the two years of the project.

Made from selected bitumens, limestone filler and specially graded aggregates, the flexibility and the fast curing time of the chosen mastic asphalt screeding system enabled BriggsAmasco to achieve precise falls quickly and more efficiently to level out uneven substrates.

The deck had previously been protected with an asphalt-based system and as part of the refurbishment, BriggsAmasco carried out a ground penetrating survey to ensure the quantity of removed material was accurate. This resulted in saving the coring of hundreds of test holes. The team were also able to pre-design the new falls that had to be introduced using the mastic asphalt screeding system, therefore providing cost and time savings which are not always possible with refurbishment projects.

BriggsAmasco also embarked on a research and development programme that brought about an innovative new 6mm chip finish to the mastic asphalt screeding system in order to provide improved skid resistance, an enhanced appearance and indentation resistance.

Mastic asphalt screeding systems are particularly well suited for use in projects where the screed needs to be trafficked or overlaid quickly, due to the rapid cooling process and fast-track application. Mastic asphalt has zero water content, which eliminates the time taken for moisture to evaporate in traditional screeds.

Additionally, there is no risk of cement stained water penetrating the underlying structure. With the screed thickness itself up to 80% less than traditional materials, it is much lighter than conventional car park decking materials.

Available in three grades – light, medium and heavy – mastic asphalt screed can be supplied directly to site in purpose-built, hot-charge transporters capable of holding up to 18 tonnes of material. Alternatively, it is also available in block form for re-melting on-site. Due to the scale of this project, hot-charge transporters were utilised.

The support and early integration of the supply chain was crucial in the continued successful delivery of this challenging project. With creative planning, a customer-centric approach and the incorporation of the mastic asphalt screeding system, BriggsAmasco met client expectations to keep the prestigious project on course and help transform Birmingham New Street station into a 21st century transport hub.

This article featured within Parking Review’s online publication, TransportXtra, in May – click here to view the full article.